The most commonly asked questions about SLIC Pins

By Pivot Point

General Machine Building

Sponsored by Pivot Point

Pivot Point answers frequent inquiries, from custom sizing to unit cost, about self-locking implanted cotter pins.

“SLIC” is an acronym for “Self-Locking Implanted Cotter”. As the name implies, SLIC Pins feature a spring-loaded plunger that functions as a self-contained cotter pin.

Since their introduction into the market over 15 years ago, millions of SLIC Pins have been implemented in thousands of applications across every industry. When it comes to technical questions, we’ve seen them all. We’ve assembled a list of the most frequently asked questions about our SLIC Pins:

What are the common sizes?

SLIC Pins are custom made to any length in common diameters from 3/16 up to 3/4 inch, including 6,8,10 and 12mm.

Materials?

The SLIC Plunger itself is made from 316 stainless steel and the underlying spring is 302 stainless steel. The body of a SLIC Pin can be made from virtually any material so long as it does not exceed Rockwell 40C in hardness, including carbon steels, Grade 5 and Grade 8 equivalents, Stainless Steels, Alloy Steels, Aluminum, and more. SLIC Pins most commonly feature a cold formed body, but more complex designs sometimes utilize a machined body with threads, flats, taps, grooves, through-holes, multiple plungers, and other features. Pivot Point can apply virtually any finish to a SLIC Pin prior to installing the plunger.

What is the standard?

SLIC Pins are not covered by any international standard. However, most clevis pin standards (ASME B18.8.1, ISO2341, DIN 1444, SAE J493, etc…) can be referenced to develop a SLIC Pin with the dimensions/materials/finishes of industry standard clevis pins, but utilizing a SLIC Plunger instead of a hole for cotter pin, or instead of a groove for e-clip or retaining ring.

Isn’t this just like a Ball Detent Pin?

While SLIC Pins and Ball Detent Pins look similar, there are host of differences. Exhibit A demonstrates both the similarities and differences between these two labor-saving solutions:

Exhibit A

How strong is the plunger?

As with any fastening solution, the answer to this question depends as much upon the specific application as it does upon the fastener itself. In a properly sized hole, the SLIC Plunger’s retention strength is comparable to a respective cotter or clip for that size of pin. Keep in mind that SLIC Plungers, as with many cotters and clips, are not intended to be load-bearing components of an assembly. These are designed only to retain the pin itself. We strongly encourage collaboration during the design stage so that we can help guide the design of your mating piece to maximize the performance and life of the SLIC plunger. Additionally, Pivot Point encourages our customers to test SLIC Pins in their applications. We’re happy to make custom samples for testing or to find some similar sizes for quick fit-check.

Can you make the plunger taller?

Each SLIC Plunger has been designed to maximize capture height for its designated pin diameter. When a SLIC Plunger is depressed to flush, there is no wasted space inside the pin to accommodate a taller plunger.

How do I remove it?

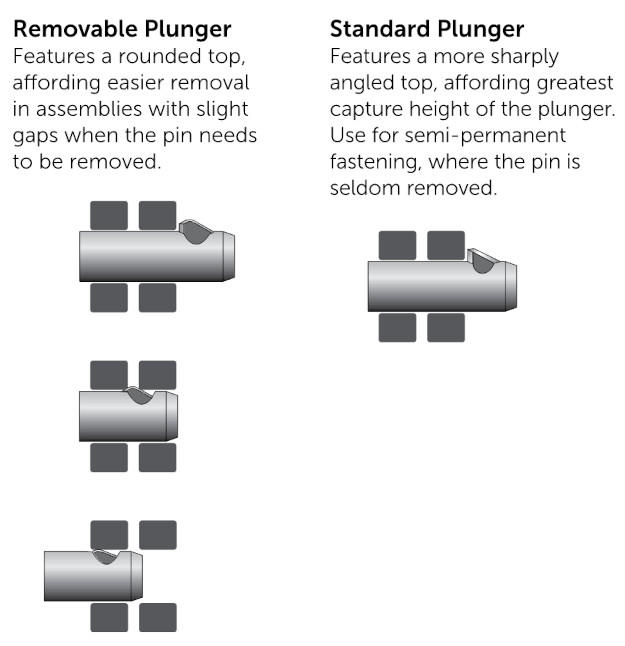

Many pins and fasteners are used in semi-permanent applications, requiring removal only for servicing, or in the case of a larger failure in the product. In other applications, the pins may never need to be removed at all. Sometimes, a pin needs to be easily removed throughout the life of the product. SLIC Pins can usually work for any of the above scenarios. The spring-loaded plunger in a SLIC Pin can be easily depressed with a finger or tool, and the allows the pin to be removed. In applications where the plunger can catch between layers of material during removal, our “Removable” line of plungers feature a radiused tip to help bridge small gaps (Exhibit B). The size of gap that can be bridged depends on the pin, and corresponding SLIC Plunger, size.

Exhibit B

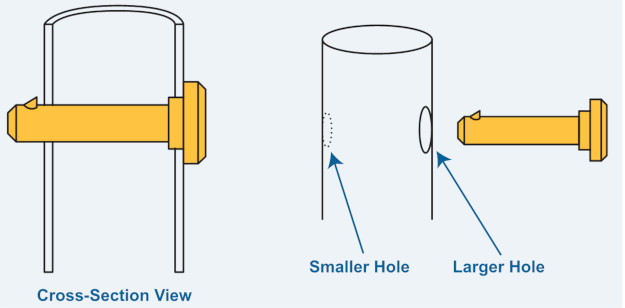

Applications with larger gaps/recesses may require depressing the plunger multiple times throughout removal in order to pass through each layer. Multi-diameter SLIC pins can streamline removal through applications where the mating hole sizes can be offset – see Exhibit C.

Exhibit C

Does a removal tool exist?

The underlying spring of a SLIC Pin has been tailored to offer robust retention, yet can easily be depressed using a finger. While a tool certainly isn’t necessary, in cases where high-volumes of pins will be removed, tools can be made to depress the plunger for rapid removal. Pivot Point is happy to aid in the design of a removal tool for your high-volume application.

Cool product, but how expensive is it?

The difference in purchase price between a SLIC Pin and a clevis pin (or other solution) is not as great as most folks expect. Pivot Point’s automation allows us to manufacture SLIC Pins at a surprisingly affordable price. Additionally, in most applications, the labor savings resulting from increased efficiency more than makes up for the initial cost difference. Actual testing shows the SLIC Pin to be at least 2-1/2 times faster than Hair Pin Cotters, which are relatively easy to install. (See Exhibit D – which clocks SLIC Pin installation against clevis pin/hair pin installation). More tedious assembly methods like nuts/bolts, extended prong cotter pins, and e-clips/retaining rings yield even greater cost savings when converting to a SLIC Pin. Commonly overlooked when comparing SLIC to other assembly methods is the cost of mis-installed clips and cotters, which can fall off later and create issues throughout the life of the product. SLIC Pins eliminate this risk, creating further value over slower and less elegant methods.

Exhibit D

Can you add a push button to a SLIC Pin for easier removal?

While the concept isn’t impossible, adding an internal spindle would reduce the amount of space inside the pin, so the plunger height would need to be drastically reduced in order to retract completely into the pin. Consequentially, the pin would end up having capture height similar to a push-button ball lock pin. Balls are much easier to use in this type of design because they roll along the internal spindle, which is why they are the prevalent design in the industry for this type of functionality. There would be very little advantage to a SLIC plunger-style push-button pin over a push-button ball lock pin.

How can I get some samples?

Just ask – Pivot Point is happy to provide samples for testing. We often make samples to your specifications, or can find similar sizes for quick sampling. Visit https://www.pivotpins.com/slic to learn more.